BCM200MT Automatic Out Layer Forming Machine for 8oz-16oz paper cups

The transmission mechanism of the BCM200MT intelligent external patch machine mainly adopts parallel shaft transmission mechanism, vertical shaft transmission mechanism, cylindrical indexing mechanism, etc., thus reasonably distributing each functional module. The split layout isolates the molding die from the transmission mechanism. The molding mold on the tabletop is easy to access and convenient for daily cleaning and maintenance; the transmission mechanism is in the enclosed space surrounded by the frame and the tabletop, using spray lubrication method; the electrical control is controlled by PLC, and the entire process is monitored and tracked by photoelectric induction. , efficient and intelligent. With automatic paper feeding and servo glue rejection, the production capacity can reach up to 150 pieces/minute. The output per shift (8 hours) can reach about 65,000 coated cups. The monthly output is more than 5.4 million pieces, and the product qualification rate is more than 99%.

| Model | BCM200MT AutomaticOutLayerForming Machine | |

| Weight | 2.5T | |

| Packing size | 2400X1000X1900(LxWxH) | |

| Electrical specifications | three-phase 380V,5KW | |

| Air source specification | 0.5-07MPa,0.3m³/min | |

| Maximum capacity | 150pieces/min | |

| Paper suction method | rotating paper suction/oblique suction | |

| Paper specifications | Gray background white board/white card | |

| Paper weight | 150-380g/㎡ | |

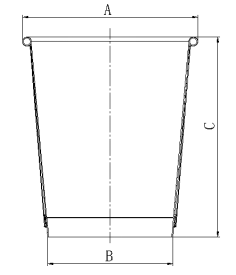

| Paper cup specifications | AΦ60-95mm | C40-135mm |

| BΦ45-75mm | ||

Copyright © Hangzhou Benchuang Machinery Co., Ltd. All Rights Reserved